Knives Buyer Guide

-

Darrian Wilkins

- Last update: February 18, 2022

Disclaimer: we may receive commissions from purchases made via our links at no cost to you

Knives have been very essential tools since the beginning of man. We’ve used them for various important activities such as preparing food, dressing games, combat, and work. Generally, there are many specific uses of knives, which has resulted in literally hundreds of different types of knives on the market today, each designed to serve its own individual purpose.

We’ll cover all the important details you need to know about knives, including their basic anatomy, the different types available out there and their uses, important things to look out for when choosing one, knife accessories to consider, and much more.

What are the various methods of knife construction?

Knives are typically constructed/produced in two main ways; they are either forged or stamped.

Forged Knives

Forged knives are made from a sheet or bar of steel heated and then hammered into shape while hot. Once the basic knife shape has been forged, the blade is heated again and taken through a grinding and honing process in order to create its final shape and edge. It’s then polished and sharpened into a finished product.

Fully forged knives are universally considered the best on the market since they are created from a single piece of steel – the blade and tang are one piece. They usually have thicker, dependable, and robust blades.

Their defining features include a bolster (the wide lip of metal) between the heel and the handle, as well as a full or partial tang – most have a full tang, which provides better balance.

The downside of forged knives is that they are often thicker and heavier compared to stamped knives. Moreover, forging is lengthy and labor-intensive, making forged knives more expensive to produce and purchase.

Stamped Knives

Stamped knives are made using a machine where the blade is cut out of a sheet/strip of steel, usually using a hydraulic press or die. This process generally creates the blade’s basic shape, called a blade blank, after which it’s ground and honed so as to give it an edge. From there, they attach the handle, and then the blade is finally sharpened and polished.

The defining qualities of forged knives are thinner blades, lighter construction, and they are typically made without a bolster between the handle and the heel.

The stamped construction process is more economical hence stamped knives are usually less expensive to make and buy than forged knives. They are also easier to handle.

However, they are not as durable as fully forged knives. Due to their thinner blades and lightweight nature, they are more prone to break, especially with repeated use. Furthermore, they tend to lose their edge quickly and require more re-sharpening than forged blades.

The fact that they are not made from one continuous piece of steel can also make them feel less balanced compared to forged knives – they have smaller or no tangs at all. They as well require more pressure and a firmer grip when in use.

Which is right for me?

Many professional chefs opt for forged knives mainly because of their reputation, and also, some prefer the thicker construction and heavier weight that they offer. Most amateur cooks will not tell the difference.

If you are a professional chef and need that extra strength and weight to withstand heavy chopping jobs, then a forged knife will be suitable. A stamped knife can be a good option as maybe a boning knife where thin and light is the main goal. It’s a great option, too, if you use your knives a lot because it will be easier to use and handle for long periods.

Generally, you are highly likely to get a quality knife when the blade is forged. That doesn’t mean, though, that a stamped knife is lower quality. The bottom line is getting what appeals to you without worrying too much, whether it’s forged or stamped.

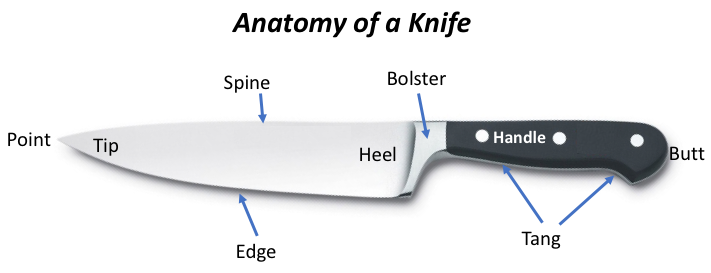

Anatomy of Knives

There are basically nine key parts of a knife’s anatomy that you need to take into account when making your decision, and they include:

1. The Blade

The blade is the whole portion of the knife, consisting of the point, spine, edge, etc. It can be in several different shapes, and it’s what determines what the knife is actually optimized for.

2. The Edge

The Edge is the sharpened part of the knife’s blade, from point to bolster. It’s the actual part of the blade that does the cutting, and it can be straight or serrated, or even a combination of the two.

3. The Point

This refers to the very tip of the blade. It’s often sharp and relatively thin, used for piercing or puncturing through products.

4. The Tip

The tip is different from the point as it’s the third of the blade’s tapered end or front quarter, opposite the handle. It does most of the cutting, curving, and separating.

5. The Heel

This is the rear portion/part of the blade, and it’s usually used for cutting tasks that need a lot of force, like cutting meat or dense vegetables.

6. The Spine

The spine is typically the unsharpened side of the blade which is opposite the edge. It can be smooth or have some sort of edge on it. The smoother spines can provide support as you can put your fingers on them, while those with some type of edge on them (double-edged knives) are for more tactical uses.

7. The Bolster/Guard

This is the thick piece of steel/metal between the heel and the handle (it joins the blade to the handle). It’s usually found on fixed blade knives and only on forged knives, not stamped knives. It serves several purposes, such as protecting the hand and adding weight to the knife to provide better balance and control.

8. The Tang

This is the metal part of the blade that’s covered by the handle. It extends fully or partially from the bolster all the way back into the handle. Its purpose is to provide balance to the knife when in use and also enhance its durability.

9. The Handle

This is the second major part of the knife, where the knife is usually held. It envelops the tangs, normally made of wood, plastic, or metal, and fastened by rivets. Rivets are basically pins that affix/attach the handles scales to the knife’s tang and are most often found on fixed blade knives.

What makes a good knife?

There are certain important factors that you need to take into account when selecting a kitchen knife to ensure you pick the one that will suit the tasks you plan to use it for. These factors are:

1. The Blade Shape

The shape of the blade is perhaps the first most important thing to consider because it’s what determines the purpose of the knife. Your choice here will depend on what tasks you plan to put your knife through. The most common blade shapes to look out for include:

Clip Point

The clip point blade features a straight cutout towards the tip (concave curve to the tip) which makes it easily identifiable since it looks like the knife’s end has been “clipped “off. It’s perfect for making faster and more controlled cuts because it’s easily maneuvered and also comes to a sharper point at the end. It’s great for detail work towards the tip and a suitable choice too for stabbing strikes.

Drop Point

The drop point features a convex curve from the blade’s spine to the tip instead of a concave curve. This style allows the blade’s tip to be ground thicker and offers more control, just like clip point blades. The difference is that the blade is curved downward, hence adding more strength to the tip than when it’s clipped off at the end, like in clip point blades. As such, drop point blades are generally durable, versatile, and quite effective at stabbing strikes.

Sheepsfoot

Sheepsfoot blades don’t really have a point as their spine usually curves down to meet with a straight edge. They look pretty similar to a cleaver, and they are generally meant for chopping or making clean slices. The spine is often smooth to facilitate more control and precision as you can put your finger onto it. Functionally, sheepsfoot blades are utilitarian, maneuverable, and non-threatening, making them safe and ideal for use in situations that don’t need a point.

Needle/Dagger Point

The dagger or needle-point blade usually features two sides/two sharp edges that taper into a sharp point that allows the knife to cut on both sides. This blade shape is generally designed to maximize piercing, making it suitable for stabbing into softer objects. The drawback is that it’s not really that durable as it can break when used on harder materials.

Spear Point

Like the Dagger blade shape, Spear point blades also have two edges for cutting. The difference is that they tend to have a small belly which allows for slicing and their point is much stronger. They are well-balanced, and an ideal option for stabbing strikes just like dagger blades. They are usually found on throwing knives, but the fact that they have a flexible, balanced edge makes them ideal for slicing as well as general EDC tasks.

2. The Edge Type

The edge is what actually does the cutting and as such, you want to ensure you pick the right type according to the tasks you intend to put it through. There are four main types of blade edges:

Straight Edge

The straight edge blades provide an edge that cuts cleanly and swiftly, and they sharpen quickly and easily. They are ideal for tasks like cutting raw meat, slicing fish, or chopping vegetables. They are optimal too for making push cuts through food, such as cutting through a thick piece of cheese or peeling off an apple’s skin.

Fully Serrated Edge

Fully serrated edges refer to blades with serrations through the entire length of the edge. They do cut as smoothly and swiftly as straight edges but do great when cutting foods with different textures (hard outside, soft inside) like tomatoes and bread. Though the serrations stay sharper for longer than a straight edge, they are much harder to sharpen once dull.

Partially Serrated

Partially serrated knives feature a half serrated, half straight blade edge. It offers the advantages of serrated and straight edges in one knife blade, making it quite flexible and easily adaptable to make the cut you need. It’s a good compromise if you are planning to use the knife for general purposes.

Granton Edge

Granton edge refers to when the blade has hollowed-out grooves in the side or, rather, scallops extending toward the middle. It’s a style meant to reduce friction and enhance the knife’s slicing ability. The hollowed-out grooves also help reduce sticking, especially when cutting moist items.

3. The Handle Material

After the blade and the edge, the third most important part of a knife is the handle. No matter how great the blade is, if the knife’s handle is poorly made and uncomfortable, you won’t want to use that knife. Therefore, choosing the right handle material is crucial, and there are quite a variety of them available, which include:

Wood

Wood is a softer material that can be pretty comfortable on the hands. The sheer amount of options to choose from is also its other benefit – the handles are made with different types of wood, from maple wood to olive wood.

However, wood has several disadvantages. First is its susceptibility to bacteria (it can easily trap bacteria). It can be hard to completely clean and sterilize a wood handle. They are equally not as durable as other materials.

Generally, if you are after a wood-handled knife, it will need extra care like hand-washing and treating with mineral oil or dedicated knife handle oil.

Laminate

Laminated handles are basically made using laminated wood composites with plastic coating/resin. They are a great alternative to traditional wood handles because they are very similar to wood in terms of appearance and weight but without sanitary issues.

They look and feel like wood but are much easier to clean and also to take care of, with added benefits such as moisture and warp resistance.

Synthetics

Synthetic handles are constructed using man-made materials, and they can be broken down into a few different categories, such as fibrox, polypropylene, plastics, and Santoprene. They are much easier to clean and maintain compared to wood handles, mainly because they don’t absorb or trap any bacteria. Most synthetic handles like Fibrox and plastic are also usually slightly textured, so they offer a comfortable and more secure grip.

The downside is that they can become more brittle and prone to cracking when exposed to extreme temperatures or even melt like is the case with most plastics. They may also wear down when exposed to UV rays. The other disadvantage is that synthetics tend to be lighter than other materials, so they may as well cause an imbalance in the knife.

G-10 Knife Handles

G-10 is a durable reinforced material made from fiberglass soaked in resin and then highly compressed and baked. It’s a process that makes it physically stable under extreme temperature and totally impervious to liquid. These handles are usually lightweight, durable, and resist corrosion – they can withstand great abuse from blows and strikes to torsion and even chemical abuse. G-10 is also incredibly grippy in hand, even when greasy or wet.

Stainless Steel

Stainless steel handles are extremely durable, sanitary, and easiest to clean and maintain compared to all the other handle materials. The downside is that they are too heavy such that they can shift the balance of a knife toward the handle, thereby causing hand fatigue.

The other issue is that they can become very slippery when wet, but some have ridges or bumps to provide a better grip. Generally, if you want a budget-friendly knife with significant, substantial weight, a stainless steel handle is the way to go.

Aluminum

Aluminum handles can be found on various knives, from the most affordable, budget-friendly options to premium custom-designed knives. They are very popular mainly because they are lightweight, affordable, anti-magnetic, and customizable.

They can be anodized for extra protection and any color under the sun (hard anodized coatings provide superior scratch resistance). Moreover, anodized or coated aluminum tends to have a powdery and grippy feel – it’s often secure and comfortable to hold.

Overall, it’s important to select a knife handle material that’s durable and offers proper grip while being soft and comfortable to hold. It should fit the contours of your hand comfortably – it shouldn’t have sharp or angular edges that will create pressure points in the hand as you are likely to get bruises after chopping, cutting, and slicing foods.

You would also want to consider the size of the handle – if you have small hands, a knife with a small-sized handle would be ideal as a big handle might cause discomfort. The bolster is equally worth taking into account. Some handles have smooth bolsters, which are preferable because your forefinger gets to rest comfortably on top, unlike handles with rough bolsters.

You also want a handle that’s easy to keep clean, so watch out for materials that can trap bacteria and bits where crud can easily get lodged and become hard to wash. We would recommend knife handles that are impervious to liquid and have no gaps at all.

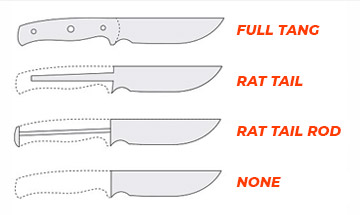

4. The Type of Tang

The tang comes in different shapes and lengths, so it’s important to know which type your knife has because they provide different kinds of support/weight. The three main tang types to look out for are.

Full Tang

Full tang knives are where the blade seamlessly runs down the whole length of the handle. They usually have better balance and are highly durable due to their more robust design –they are often secured by rivets, which eliminate the danger of the handle material coming loose from the blade. They are the best choice for professional chefs and avid cooks.

Half Tang

In half tang knives, the blade extends halfway into the handle. There are some though where the handle extends three quarters into the handle. While they are not as high quality/durable as full tangs, they are still suitable for general everyday cooking and are more economical. The downside is that they just glue bind the knife and handle, hence running the risk of snapping if too much force is applied.

Rat-tail Tang

In rat-tail tang knives, the blade narrows as it extends into the handle, and it’s commonly welded at its base. This type of tang isn’t the most reliable option because it can come loose over time, thereby making the handle wobbly.

In general, as far as tangs are concerned, a good knife is one that has a full tang that extends the whole length of the handle, and it’s riveted. This will give the knife both strength and stability – it will feel well-balanced when in use.

5. The Point, Tip, and Spine

The sharpness and placement of your knife’s point is a vital factor to consider. The thinness and angle help determine not only the level of control you have but also the strength and the type of foods you can cut. A sharp and relatively thin point is the way to go for best results when making incisions, carving, and cutting.

The tip of your knife is equally important to consider, especially if you plan to make finer cuts. Here, you have two options, point tips, which are best for cutting and piercing small portions, and rounded tips, which are more fine-tuned for slicing or cutting thin portions.

The spine is another thing you need to look at. It can be smooth or have some edge on it. Smooth spines are great as you can use them for support because you can put your finger on them.

6. Weight and Balance

The weight of a knife needs to be balanced equally between the blade and the handle. You can check this by laying the knife across the middle finger and forefinger at the bolster or heel (where the blade and handle meet). If it tips, then it’s not balanced, and that’s going to be a problem. If the knife handle is too heavy, then it won’t cut as effectively, while if the blade is the one that’s too heavy, then it will be uncomfortable to use.

Therefore, a good knife needs to have the weight in the right place, which is usually right on your thumb and index finger when you’re gripping it (or at the heel or bolster), not at the butt of the handle. However, that can change a bit with different knives.

A cleaver, for instance, needs to be blade-heavy to chop through bone as that’s where the work happens. On the other hand, a paring knife needs to be light to glide effortlessly around a potato, whereas a chef’s knife needs to have some weight behind it, as most experts would agree.

Generally, there’s no ideal weight. You want to make sure that the weight of the knife is appropriate to the job it will be doing. Beyond that, it’s a matter of personal preference. If you want a knife that guides itself slightly more, then a heavier blade is ideal. If greater control is what you are after, then a lighter one would be ideal. However, you want to ensure you don’t pick a knife that’s so heavy that it will strain your wrists when in use.

Types of Knives

There are many different types of knives, each designed to serve a particular purpose (s). The list below details the most common types of knives, categorized by purpose.

General Kitchen Knives

1. Chef’s Knife

Also called a cook’s knife, the chef’s knife is arguably the most frequently used in the kitchen. You can use it for almost any kitchen/food prep task, including slicing, cutting, chopping, and dicing. It features a long, broad blade that tapers to a point and has a straight edge. It’s equally widespread across the heel and has a smooth spine. The slightly curved cutting edge allows for a rocking cut, ideal for dicing various vegetables at once.

It’s available in several different blade sizes/lengths, typically between 8 and 10 inches, but it can be as long as 14 inches and as short as 6 inches. The best length here is one that you feel comfortable with and will ensure ease of use and the most versatility – the longer it is, the more cutting space it will provide.

2. Paring Knife

This is another essential and versatile kitchen knife that’s often used for precise cuts. It’s basically similar to a chef’s knife, but it’s small and has a short blade that’s evenly sized to the tip. The blade usually ranges between 3 and 4 inches in length and comes in several different styles/shapes.

There are those with a spear point shape, while others have a bird’s beak shape where the blade curves downward, resembling a bird’s beak. You can use these curved paring knives both on a board and in hand. There’s also the sheepsfoot shape which is suitable for use only in hand.

These knives are suitable for the same tasks that a chef’s knife does, but on a smaller scale, especially when more precision is required – they are smaller and capable of making detailed cuts when peeling, deveining, mincing, dicing, and deseeding. They are also ideal for creating garnishes such as swans made out of potatoes or flowers made out of tomatoes.

However, you can only use them on soft vegetables and fruits. They are not suited for carrots, beets, or squash because you’ll have to apply an unsafe amount of force due to their lightweight, which can lead to injury.

3. Utility Knife

A utility knife, also known as an all-purpose knife, is a mix between chefs and paring knives. It features a scalloped edge, a small tip, and a narrower blade than a chef’s knife but longer than a paring knife. It looks pretty much like a chef’s knife and even has the same function, but it’s smaller and extremely versatile. It generally measures around four to seven inches long.

You can use these multi-purpose knives to do almost everything in the kitchen, from cutting, slicing, trimming, and chopping to de-boning and filleting. They are perfect for prepping food, especially those that are too small for chef knives.

4. Bread Knife

The bread knife is also part of the basic kitchen knives, and as the name suggests, it’s designed for just one purpose: to cut bread. It features a long, fully-serrated blade that creates a sawing motion that allows you to easily cut through coarse loaves/soft bread without crushing them or using unnecessary arm power. Plus, it produces fewer crumbs than a regular knife for cutting bread. It can cut through both soft and crusty bread, including baguettes, bagels, and more.

The bread knife can also be used for slicing cakes for serving as it’s able to cut through the layers easily without freeing the air from the sponge, thereby keeping the shape of the cake intact. It can as well be used for other tasks too like cutting soft or large fruits such as tomatoes and melons.

Most bread knives are seven to 10 inches long and have offset handles, which help prevent the knuckles from hitting the cutting board.

Special Kitchen Knives (Meat Knives)

Special kitchen knives are knives with unique blade types designed for specific purposes or tasks in the kitchen. Most of these are meat knives, but our list below includes several other options like special vegetable knives.

1. Boning Knife

The primary use of boning knives is separating meat from bones, which they do effectively without wasting much meat. These knives feature a thin and very sharp blade that’s usually 6-inches long and tapers off to a fine upturned point.

They have a relatively rigid construction with a chunky handle that provides a solid grip and makes it easy to use the knife at different angles.

Their thinness makes them somewhat flexible. They are able to move with the bends and curves of the bone to get into areas that are tough to reach and separate the meat effectively. They can cut around bone without really damaging the surrounding flesh.

Note, though, that there are two versions of boning knives, each having a specific purpose. One variety features a flexible blade which is ideal for removing skin and cutting through more manageable meat like poultry and fish. The other features a robust and rigid blade suitable for use with greater force when working with thick or large pieces of meat such as beef and pork.

2. Butcher’s Knife

Butcher’s knife features a large blade that has a deep belly. The blade can be 14 inches long and has a clip point. It’s an essential knife in the meat-processing industry as it’s often used for professional butchering work in butcher shops and restaurants. It’s mainly used for butchering and dressing animal carcasses, breaking down large cuts of meat, or trimming the fat.

The broad, curved blade offers additional leverage when splitting and cutting through tough skin, cartilage, or small bones. Most butcher knives also have Granton edges that allow you to slice through meat easily without shredding or tearing the product.

3. Cleavers

Cleavers are sometimes referred to as butcher’s knives, but they are nothing close to the butcher’s knife described above as they have a much bulkier blade design. They are big knives with a flat, rectangular-shaped blade that’s wide, long, and very tall.

Their large, heavy-duty design makes them the only ideal knives for tackling tough jobs. They are strong enough to chop through meats and bones like the humerus, and it doesn’t really have to be extremely sharp to be effective. These knives can be used on beef, pork, poultry, and other meats, primarily for cutting through bones and hunks of meat.

Some people also use the side of the blade (the large flat, heavy surface) to crush garlic cloves or ginger against a cutting board. The backside of the blade can as well be used to chop vegetables. Cleavers also often have a hole near the spine that allows you to hang them when not in use easily. They are not particularly common in home kitchens, but many butchers and chefs in restaurants use them.

4. Carving Knife

The carving knives are an ideal choice when you want to make clean, precise cuts. They have noticeably long, thin blades with smooth cutting edges that can cut/carve clean and even slices of meat. A good carving knife is usually 15 inches long, which is ideal for even the biggest turkeys, but there are other smaller options like 7 inches knives, suitable for small pieces of meat.

These knives can be used on various types of meat and fish. They are perfect for slicing or carving cooked meats such as roasted chickens, smoked ham, or deep-fried turkey.

The blades are much thinner than chef knives, enabling them to carve thinner and more precise slices, plus there’s less leakage of valuable meat juice than when using a chef’s knife or any other ordinary knife. Some even have indentations that help stop the meat from sticking to the surface.

5. Fish Knife

Fish knives tend to have thin and flexible blades that can remove the skin with care and be used to cut raw fish, which can be a delicate task. There are several different types depending on the size and kind of fish you are handling.

The filleting knife is the most common option, and it features a long, slim blade that can be anywhere between six and 11 inches long. It’s virtually similar to a boning knife in terms of design but offers greater flexibility. This slender knife specializes in fish preparation. It’s mainly used for separating fish skin from flesh and cutting around bones in fish.

The salmon knife is the second option, designed for use on larger fish such as salmon. Fish might be larger, but their flesh is still delicate hence a proper knife is necessary, and the salmon knife is the best option because it’s able to cut between the fish skin and flesh effectively without causing damage. Some even have indentations along their blades which reduce drag and help keep the raw fish flesh and skin from sticking to the blade’s surface.

Table Knives

With your meal prepared and served, it’s time to sit down to enjoy it, and that’s where the table knife comes into play. They are essential tools used while eating and come in a wide variety, each serving separate purposes. Here are the most common options:

1. Butter Knife

A butter knife/butter spreader is one of the smallest knives available, and it’s used primarily for spreading butter, jelly, or other toppings onto bread and other breakfast pastries. It features a broad paddle-like blade with a blunt edge (dull and rounded) that glides smoothly through and spreads the butter (or other toppings) without affecting/damaging the surface of the bread. Moreover, the point is rounded (not pointed) to ensure it doesn’t rip the bread off.

2. Cheese Knife

A cheese knife is a special type of kitchen knife designed specifically for cutting cheese. It comes in different shapes and sizes and has different sharpness levels depending on the specific type of cheese you want to cut – soft or hard cheese. The most common types are the ones designed to cut soft cheese, but there are those specially designed to cut dense, sticky, and hard cheeses. Most also have holes in the blades to help cut cheeses without them sticking.

3. Dinner Knives

A dinner knife is distinct from the other table knives as it has the longest blade. It’s usually made from stainless steel or other metal and has a slightly serrated edge for cutting through tougher foods. It’s specifically used for cutting soft foods like fish and cooked vegetables and for moving food. It can as well be used to cut bigger salad leaves in case there’s no salad life, or even for spreading butter in the absence of a butter knife.

4. Dessert Knives

Dessert knives resemble dinner knives, only that they are smaller. They are mainly used for dessert and fruits – they are almost double the size of a butter knife, hence are able to cut through soft items such as cakes and cheesecakes easily.

5. Steak Knives

When serving steak or a thick piece of meat that can’t be cut with a dinner knife, then a steak knife would be the best choice. The blade of this knife features a more severe serrated edge and comes to a sharp tip. It’s probably the sharpest blade of all table knives, and it’s rightly so in order to enable it easily cut through very thick or tough pieces of meat.

6. Fish Knives

Similar to dessert or butter knives, fish knives are small and ideal for use when eating fish. These knives have flat blades, complete with curved edges. It’s a design that makes it easier to remove the skin from fillets and also to weed out small bones from delicate pieces/slices of fish.

What is the best steel for knives?

Knife blades are typically made of steel and the blade being the heart of a knife, the type of steel used to make it is certainly a very important factor to consider because it will determine the quality and performance of the knife.

1. Stainless Steel

Stainless steel is the most common type of steel used to make knives. It’s referred to as stainless steel because it contains a certain amount of chromium (Cr) which varies from one type of stainless steel to another, but it’s usually around 10.5% or more.

It’s the chromium in the steel that makes it resistant to corrosion, decay, and wear. For this reason, the main benefit of stainless steel blades is the fact that they don’t rust easily. They don’t stain or discolor either, which is particularly advantageous in kitchen knives since food and its juices get on the knife, thereby increasing the potential for stains.

However, while stainless steel excels in corrosion and stain resistance, it suffers in performance. It’s simple to sharpen, but it doesn’t keep the sharp edge for long like some other blade materials (carbon steel). As a result, it requires re-sharpening more frequently than other materials. Obviously, not all stainless steels are the same since there are several types that offer different levels of quality.

The Good

These are entry-level stainless steels that are typically made in Asia. They are rust-resistant and offer good value. However, they tend to be softer than higher-grade stainless steel and do not adequately hold an edge. Hence, they require more frequent re-sharpening to maintain the best performance. Some examples include 420, 420HC, 440A, and AUS-6 stainless steel.

420 steel is US-made steel that’s common in lower-end knives. It has a low carbon content (about 0.38%), making it very soft compared to most other steel. It doesn’t hold an edge well, but it’s extremely easy to sharpen and is highly rust-resistant.

420HC stainless steel is similar to 420 steel but has a slightly more carbon content (0.4 to 0.5%), making it harder. It provides excellent rust resistance, is extremely easy to re-sharpen, and offers good edge retention.

440A is much like 420HC steel but with even more carbon (0.65 to 0.75%). The slightly more carbon content results in a significantly stronger blade, high wear resistance, and enhanced levels of edge retention. However, it’s much more prone to corrosion than 420HC.

AUS-6 is Japanese-made steel, comparable to the 420 steel but with relatively good carbon content (0.65%). It offers better edge retention than 420 steel and resists corrosion reasonably well, but it’s still soft steel that’s generally considered low quality.

The Better

The better-grade stainless steels have higher chromium content. They are more expensive but offer greater edge holding ability, requiring less maintenance than the entre-level grades of stainless steel. Sharpening them is also fairly easy. They offer a great balance of value and performance and are perfect for everyday use. Some good examples are 440C, AUS8, and 8Cr13MoV stainless steel.

440C is typically considered high-end steel. It has higher carbon (0.95 to 1.2%) and chromium levels than its counterparts in the US-made 400 series, which makes it harder. It’s reasonably tough, can hold the edge better than the other 400 series steels, and excels at wear and stain resistance. The blades can also be sharpened relatively easily. However, it falls a bit short when it comes to rust resistance.

AUS-8 is Japanese-made and is also considered high-grade steel. It boasts a good edge holding ability, and it’s slightly more resistant to corrosion and rust than 440C but less hard.

8Cr13MoV is Chinese-made stainless steel equivalent to the AUS-8 but has a slightly higher carbon content, making it slightly less corrosion resistant. However, it retains the edge very well, is tough, and fairly easy to re-sharpen. It generally offers a great performance-to-cost ratio.

The Best

These are typically stainless steel made in Japan and the USA. They have higher chromium content, and as such, they come with a cost premium. Other elements like vanadium are often added to create superior edge sharpness and retention and enhance rust resistance. They are tough stainless steels, ideal for more demanding uses. VG-10, S30V, and CPM 154 stainless steel fall in this category.

VG-10 is a high-end Japanese stainless steel that’s typically used to make professional-grade knives. It contains more chromium and vanadium, which increases its toughness and corrosion resistance. Moreover, this steel is prized for its excellent edge retention and sharpness. It can be sharpened to a very fine edge that’s durable and can keep a hardness of up to Rc 60 without becoming brittle.

CPM S30V is made in the US and is actually powdered steel (CPM steel) consisting of 10.5% chromium carbide, 4% vanadium carbide, and 1.45% carbon. It has high edge retention and great wear resistance, plus it’s very tough. The introduction of vanadium carbides adds extreme hardness into the steel, making it super tough and much more effective at cutting than steel with just chromium carbides. It’s generally regarded as one of the best steel for knife making, offering the optimal balance of hardness, toughness, and edge retention.

CPM 154 is the powdered version of the 154CM steel, produced using Crucible Particle Metallurgy which makes finer carbide particles that result in a slightly superior stainless steel that’s tougher and offers better edge retention with excellent levels of corrosion resistance. Grinding it is incredibly easy too.

2. Carbon Steel

Non-stainless steels that have a carbon content of about 1% are considered carbon steels. They usually have higher carbon content than stainless steel but less amounts of chromium, although they often include alloys such as vanadium and manganese.

Carbon steels have generally been valued for their ability to hold an edge. Their higher carbon content makes them strong, easier to sharpen to a fine edge, and able to retain their sharpness/cutting edge for a long time. As a result, they are slightly more expensive compared to regular stainless steel knives but still reasonably priced than the high-grade stainless steel knives like VG-10 and S30V.

The major disadvantage is their susceptibility to stains. They tend to discolor, especially when used with acidic foods like citrus fruit and tomatoes. Carbon steels are also prone to rust when not completely dried after usage, so they require more care and maintenance than stainless steel knives.

3. High Carbon Stainless Steel

As the name suggests, high-carbon steels have a higher carbon makeup(more than 1%) than carbon steels or regular stainless steels. They are essentially higher-grade steels that provide the best of both worlds. Due to the higher carbon content, the blades are stronger and offer great edge retention and cutting ability while resisting rust and discoloration.

They are basically able to hold a sharp edge longer and can be sharpened over and over again should they become blunt. However, these premium knives are more expensive than both stainless and carbon steel. Additionally, there’s no industry standard that really defines what high-carbon steel is, so some knives may claim to be carbon steel on the label yet their carbon content may not actually be more than 1%.

4. Damascus steel

Damascus steel comprises a carbon steel core encased by stainless steel, which has been hardened and tempered to create alternating hard and soft layers. These knives are incredibly strong and can easily be ground to be razor-sharp. They are often handmade and have striking designs along the blades, which distinguish them from other steels, but can be expensive.

5. San Mai Steel

San Mai means layered steel, and it’s nearly similar to the Damascus steel in that it contains a very hard, high-carbon steel core, encased in softer, more resilient, and flexible outer layers (usually consisting of lower carbon steel). Its major advantage is that the blade offers excellent edge retention and sharpness (has an extremely hard edge) while maintaining flexibility.

To sum it all, whatever type of steel you go for, the key thing is to ensure it’s of good quality, which means it should have good edge retention, easy to re-sharpen, and be rust and stain-resistant. If you opt for high carbon steel knives, then you’ll be guaranteed a durable blade with a sharp and precise edge that can be easily sharpened time and time again. It will also be able to maintain a stain and rust-free finish.

What knives do chefs use?

Chefs may generally have different consensus about which type of knives are the most essential. However, if we are to narrow it down to the bare essentials, then these three are the most important knives that any chef will use.

Chef’s Knife: a chef’s knife is a workhorse. It’s multi-functional. It can be used for food processing (chopping, dicing & peeling), garlic pressing (grinding & smashing), a shell cracker, and for many slicing tasks and more. A chef could easily get by with it only as it can pretty much handle everything in the kitchen.

Paring Knife: this is the second must-have knife for any chef. It’s essentially a mini chef’s knife ideal for delicate tasks like fine cutting and peeling small vegetables and fruits, coring tomatoes, or trimming vegetables.

Serrated Knife: this is the last essential knife, although not to all chefs. It’s most useful for slicing foods with varying textures (hard outside, soft inside) like hard-crusted bread, tomatoes, and even meat. It lets you cut or slice the food without damaging its appearance.

Knife Accessories and Storage

You’ll likely need several knife accessories to help keep your blades in top shape and to support your knife collection. Below are some of the necessary accessories and storage options that are worth considering.

Knife Sharpener

A knife sharpener is a must-have accessory that will help keep your blades sharp and fresh, making them safe and more efficient tools. They come in different types, including manual, electric, and sharpening stones. A manual knife sharpener such as a steel rod is perfect for sharpening stainless steel kitchen knives, while the electric knife sharpener is ideal if you want a more automated approach and can sharpen both kitchen and outdoor knives.

Sharpening stones, on the other hand, are more convenient for sharpening hunting or outdoor blades. However, there are also longer sharpening stones that are perfect for kitchen knives.

Knife Storage

Learning how to store knives safely is essential, and below we’ve shared some effective ways to do so.

1. Knife Block

Knife blocks are made using a variety of materials such as bamboo, wood, and stainless steel. They also come in several styles. Some feature the traditional knife block style where knives go into small slits at an angle, while others have the knives sit in a vertical or horizontal position.

Their advantage is that they allow you to get your knives out quickly when cooking or when you need them. They normally have varied-sized slots to accommodate different blade types. They are simple to use, offer a nice presentation of the knives, and don’t take up a lot of space, making them ideal for those short on space.

The downside is that they can be difficult to clean – it can be difficult to get right into the small slits. You have to ensure the knives are clean and dry before placing them away to avoid mold and bacteria growth in the slits. Some knife blocks also tend to dull knives. As you pull them out, the blades drag against the wood. Luckily, you can solve this by getting a block with horizontal slots to ensure the knives don’t rest on their blades or place the block on its side.

2. Magnetic Knife Strip

This is a long, horizontal, magnetic strip that’s attached to a wall above a countertop. The knives stick to it, and they are securely held in place and allowed to air dry properly. It’s a great option if you have stainless steel kitchen knives because it won’t blunt the blades.

Unfortunately, the wear is transferred to the tang since you have to pull with some pressure to release a knife from the strip, which can cause the tang to weaken with time and even probably snap in case it’s a low-quality knife. The other downside is that the knives are more exposed, which could be a hazard if you have kids in the house as the knives are easily accessible.

3. Knife Bag

A knife bag keeps your knives separated and well protected more than the other storage method. It’s quite inconvenient for your home kitchen, though. It’s only good for the transportation of knives.

4. Knife Cases

Knife cases provide another effective and safe way of storing knives. They usually have slots that can fit kitchen knives of different sizes and shapes – the handle of the knives go into the slots, not the blades. Knife cases also feature a hard lining which holds its shape once the case is closed or folded. This lining can as well be water-resistant hence adding another layer of protection to the knives.

5. Knife Rolls

These heavy-duty cloth organizers feature individual slots for each knife where the handle goes in, not the blade. Once the knives are properly set, they are easily rolled up, thereby taking less space compared to knife bags or cases. They are a great option for easy transport (for chefs who travel from restaurant to restaurant) or outdoor knife storage, like in a backpack.

The downside is that they don’t have a hard lining under the canvas exterior, so they lack that protective layer that can help keep the knives away from contamination.

Like knife cases and knife bags, some knife rolls have additional slots to store other kitchen tools and utensils, such as spoons, turners, and whisks. Others even have holders for pens, IDs, and business cards.

6. Drawer Organizer

A drawer organizer or drawer tray is an ideal option if you want a more discreet solution that can also prevent your kitchen knives from dulling each other. It offers specific places where you can insert your knives such that they don’t rub against each other.

It’s pretty convenient as it keeps your knives well organized without being displayed or exposed, making it safe if you have small kids or pets. However, it does have some of the downsides of the knife block, like it can hold some water when you store the knives without drying them properly, which can possibly lead to contamination.

Where to buy knives

You can buy knives from online or physical stores. Buying online is easier and hassle-free since you get to do it right from your computer. You can find a wide variety of knives and shop without wasting much time, which is a good advantage.

The main issue is that you order and receive the knife without trying it out. You don’t get to feel it in your hand and judge it physically to see if you like it or if it’s the right one for you.

Another disadvantage is that sometimes you may not get the exact thing you saw online, or the quality might be bad. There’s a prevalence of counterfeit and substandard knives, and often the pictures online are modified to make them look better or more attractive.

The probability of getting duped online is high, too, especially when the retailer asks for upfront payment after ordering a particular knife. That’s why you have to be sure to purchase a knife only from reputable and well-established online retailers so that you can be confident that you’ll get a product that’s 100% original. Thorough research to confirm the authenticity of the retailer can also help save you from a fake product.

It’s generally very important to try out knives before purchasing them, as our hands differ in size and shape. This is why nothing can beat physical stores since you can go and sample some knives before proceeding to make a purchase.

So, the first step to finding the knife that works for you is to physically search out a cookware or cutlery store with a broad selection of sample knives which you can browse and handle or even maneuver on a cutting surface. You can get a feel of different knives and also see how they look in real life, unlike online, where pictures are usually modified – the only good time to buy online is when you can’t find the knives you want from your local retailer or cutlery store.

The other advantage of a physical store is that you can get assistance from knowledgeable staff members who can guide or talk you through the advantages and disadvantages of each knife and even help you find that ideal knife that you after.

Besides that, there are specialty knife stores that stock specialty knives like Japanese knives or bespoke chef knives. These are ideal places to check when looking for specialty knives, especially those hard to find in regular physical stores.