Best Wood for Knife Handles

-

Darrian Wilkins

- Last update: February 11, 2022

Disclaimer: we may receive commissions from purchases made via our links at no cost to you

A knife blade functions well when it’s paired with a strong, durable handle that’s comfortable to hold and offers a solid grip when cutting or slicing. Although there are many materials used to make the handle, wood is probably the most popular and oldest choice. It has been used for making knife handles since knives came into existence and there are good reasons for that.

The most compelling one is the fact that it’s a common natural material that’s available almost all across the globe. It’s eco-friendly and renewable when properly sourced and sustainably grown which makes it abundant and easier to access in contrast with other materials such as plastic, metal, and stone. Plus, you don’t really need much to make a handle as even leftover wood blocks can work. It’s one of the best materials for eco-conscious knife makers.

Wood can also provide a firm and comfortable grip. It can have an excellent, textured feel and can be easily carved into an ergonomic shape that fits perfectly in the hands. Wooden handles are also naturally shock resistant, which makes it a lot easier to use the knife for longer periods and even at higher levels of exertion.

Good quality wood handles are tough and long-lasting too. They can withstand regular use for years or even decades if well finished and well-maintained. Some species of wood, especially hardwoods and stabilized woods are even compatible with water. They won’t decay in wet conditions, plus they can endure heat well, although you’ll have to deal with some visual imperfections.

Wood handles also have an aesthetic appeal. They complement metal very well. They are the best choice for making ornamental and custom-made knives that offer classic, beautiful, and attractive looks. Wood does provide a variety of creative possibilities as it’s easy to carve and shape into a design you want. Making wood handles is fairly inexpensive also and there’s a wide variety of woods to choose from which come in various colors and grain patterns.

Generally, wood offers many benefits and that’s why it has always been the popular choice for knife handles. In this post, we’ll discuss the categories of wood available out there as well as some of the best wood for knife handles. We’ll also look at how to make a wood knife handle, plus other common questions about wood that you may find useful. So, let’s jump right in.

Hardwood vs. Softwood

Wood is available in a wide variety, but there are two or three main categories. Overall, most wood you’ll find will fall under either hardwood or softwood.

Hardwood

Hardwoods typically come from angiosperm trees which are color-changing trees that feature broad leaves and reproduce through flowers. Many of these trees are deciduous, meaning they shed their leaves every autumn when in temperate/mild climates or during seasonal droughts when in warmer/tropical climates. Some good examples of hardwood trees include maple, oak, mahogany, balsam walnut, rosewood, beech, and alder. In tropical and subtropical regions, hardwood is usually taken from evergreen trees.

Just as the name suggests, most hardwoods are generally more physically dense and strong. They are harder and more resistant to penetration than their softwood equivalents. A few exceptions do exist like balsa which is a hardwood but it’s softer than most softwoods.

Overall though, hardwoods are the best choice for knife handles because they are dense, strong, and durable. They can easily maintain thin sections and also fine curves such as finger grooves and flutes without chipping, splintering, or breaking.

Softwood

Softwoods largely come from gymnosperm trees, mostly coniferous trees such as spruce and pine. Yew, cedar, juniper, redwood, and Douglas fir are also some good examples of trees that are notable sources of softwoods. Unlike hardwoods, these trees have needle-like leaves and usually bear their seeds in cones. They are also deciduous (don’t lose their leaves in autumn) and they grow more quickly compared to hardwoods.

Softwoods are typically less dense and less resistant to penetration in contrast with hardwoods. They tend to be much more porous and malleable. However, a few exceptions do exist too when it comes to softwoods and a good example is wood from yew trees which is a kind of softwood but harder than some hardwoods. Yellow pine, Douglas fir, and hemlock are also some good examples of stronger softwoods. Overall, though, softwoods are hardly used for knife handles.

What about Stabilized or Untreated Wood?

Stabilized wood is a whole different kind of wood altogether. It’s a wood that has gone through a stabilization process where it’s dried, infused with chemicals, and then compressed under high pressure in order to stabilize it or rather reinforce it against defects or inherent weaknesses. A few examples of stabilized woods include Pakkawood, Dymondwood, and Staminawood. All these are plywood typically made from the birch trees.

The stabilization process involves immersing the softwood (mostly birch) in a pot of polymer resin (penetrating resin) inside a vacuum chamber. The wood has to be completely dry (moisture level below 10%) since wet wood won’t absorb the resin which will render the wood unusable.

Inside the chamber, the softwood is subjected to intense vacuum pressure which pulls all the air right out of it and then the vacuum is released to drive the polymer resin into the wood capillaries. The resin replaces the air, filling all the porous parts of the softwood.

All the air has to be pulled out of the wood and this is noted when the pot stops bubbling, meaning the resin/stabilizing solution has infiltrated the wood pieces fully and it’s now ready for curing (to be transformed into a solid-state).

It has to be cured properly or otherwise, the wood won’t stabilize. The curing process involves putting it in an oven up until all the polymer resin hardens and bonds with the fibers or cellulose in the wood, thereby creating a linked plastic network in the entire structure of the wood. This would take probably an hour or so, upon which the wood needs to rest for around 48 hours before anything else can be done with it.

This whole stabilization process hardens the softwood and makes it very dense, hence giving it the strength and durability it requires to be usable for making a knife handle. It drastically improves its wear resistance making it less susceptible to warping and cracking compared to natural, untreated softwood species. It also prevents decay from humidity as it’s practically waterproof which equally makes the handles suitable for wet applications such as kitchen use or marine environments.

Besides ensuring increased strength and durability, stabilized woods are uniquely-colored and can still exhibit natural beauty. They as well easily reflect a good finish because the process of stabilization helps cover the open pores and also discards unevenness or roughness while leveling the hardness.

You can work with a stabilized wood just like you would with a dense hardwood piece – you can pretty much use the exact same tools to cut, shape, or sand it. Note though that the impact of stabilization can vary from one wood species to another. For instance, some species like ash and maple tend to gain significant weight while others like walnut and redwood will lose weight and as such, they may not be really hard. Nonetheless, they will be harder and more durable in contrast with natural softwood species.

As for the untreated hardwoods, these don’t require any sort of special processing before they can be turned into a knife handle because they are sufficiently hard and durable right off of the tree. They just need to be shaped and then polished properly to bring out their natural beauty.

Best Wood for Knife Handles

1. Best Softwood for Knife Handles: Yew

Pros

- Hard softwood that’s great for knife handles

- Has great resilience and flexibility

- Makes a very grippy and comfortable handle

- Works well in a damp or marine environment

- Great for stabilizing or dying

Cons

- Can be quite toxic if not dried properly and stabilized

- It’s not the most aesthetically pleasing wood

- Like other conifers, it’s easily breakable with regards to the grain

Why it’s the best

Yew is a great wood and is frequently used to make knife handles. It’s softwood botanically but it’s very hard and tougher than many hardwoods. It has great resilience and flexibility which makes it suitable for knife handles. It also has a smooth finish when polished but it still does provide a very grippy handle because the latewood tends to wear away more slowly thereby leaving a slight texture to the wood. It works well too in a damp or marine environment. As for the look, Yew is not really the prettiest wood but it does look fairly decent.

It features tight rings, made of tan/light orange heartwood that has Dark orange to reddish grains running through it. The grain lines make a nice contrast with the sapwood (the new growth outside part) which is quite light. The wood darkens significantly with age. It’s an absolute joy when it comes to shaping and polishing it. The major concern is that it’s toxic but once dried and stabilized it should be okay to handle day to day. It has pretty long and straight grain that makes it great for stabilizing or dying. Oiling with good oil that goes deeper into it as well helps seal it and prevent the transfer of any toxic bit from the handle to your hand.

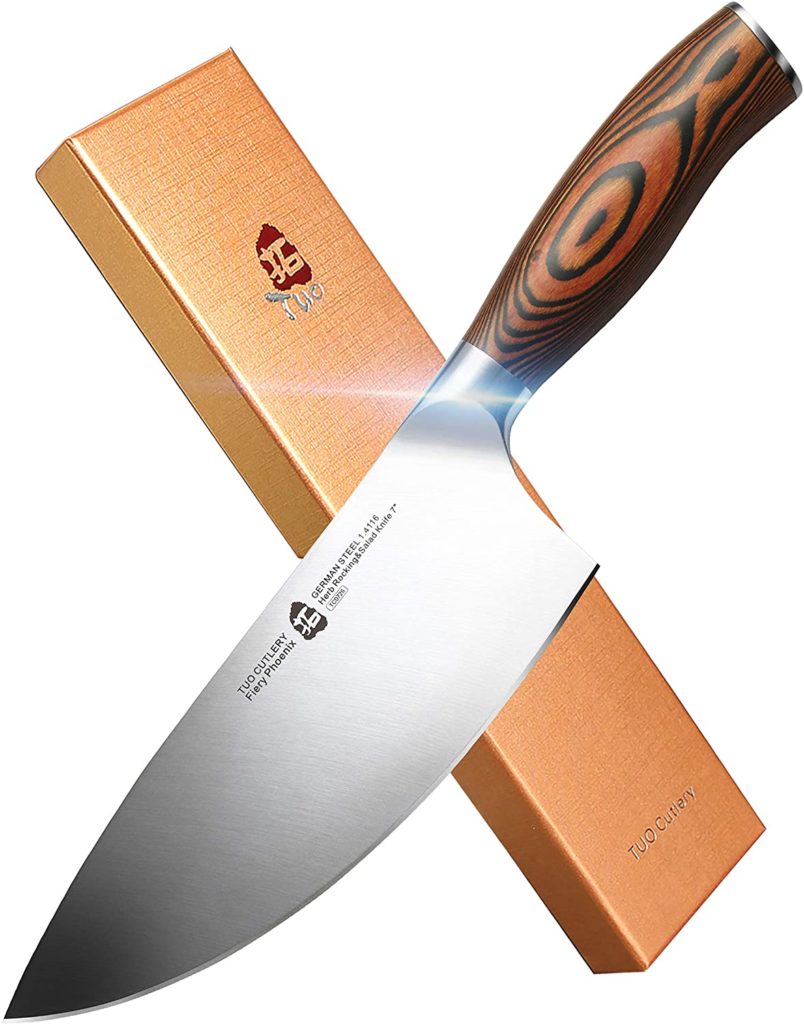

2. Best Hardwood for Knife Handle: Indian Rosewood

Pros

- Strong, hard, and very long-lasting

- Suitable for demanding uses

- Highly resistant to all kinds of damages

- Comfortable to hold and offers a fairly firm grip

- Has rich coloration that makes it aesthetically pleasing

- It’s very cost-effective and takes finishes well

Cons

- Can be a bit difficult to work with, given its density

- Tends to dull cutting edges rapidly

Why it’s the best

While rosewood is available globally, Indian rosewood is the most preferred option and it’s loved by the majority of users mainly due to its sturdy composition. It’s a dense timber consisting of narrowly interlocked grain and has small pores and a medium texture. It’s strong and extremely hard (3,170 Janka hardness rating) which gives it excellent durability and great resistance to cracks and warping. It’s perfect for knife handles, especially knives meant for the most demanding uses, such as kitchen knives as well as hunting knives. Indian rosewood is also highly resistant to all types of damages including attacks from pests like termites.

This hardwood is also comfortable to hold and offers relatively firm grip thanks to its medium texture and its malleability. Many knife makers do prefer Indian rosewood as well because of its rich coloration which provides a beautiful, attractive look. It features a lovely dark color that varies in shade, ranging from golden brown to deep purplish brown. It darkens with age, which gives it even a more beautiful and luxurious look when polished. It can make fantastic ornamental knives. Moreover, it’s very cost-effective and takes glues and finishes well, although you have to use seal coats initially as some of the resins inside the wood can easily bleed onto the surrounding surfaces when applying the finish.

3. Best Stabilized Wood for Knife Handle: Pakkawood

Pros

- Strong, dense, and very durable wood

- It’s able to hold up well to heavy, frequent use

- Highly resistant to moisture and heat

- Lightweight enough to reduce hand strain

- Has a natural glossy finish that’s scratch-resistant

- Comes in various striking colors and patterns

Cons

- Can warp over time if often soaked in soapy water

- Some find it too lightweight for professional cooking knives

Why it’s the best

Pakkawood is one of the best stabilized wood and a great alternative to natural wood. It’s typically an engineered wood, made with hardwood veneers (like plywood) impregnated with phenolic thermoset resins under high pressure and extreme heat, creating a very strong and dense wood/resin composite that’s durable and resilient enough to hold up to frequent use and daily wear and tear. It isn’t susceptible to warping, cracking, and splitting in contrast with real wood. It’s also highly water-and-weather proof due to the resin it’s impregnated with. The wood/resin combination equally makes it highly resistant to heat, so it’s suitable for use in almost all kinds of conditions in the kitchen.

This type of wood is quite lightweight too hence reduces hand fatigue when in use which makes it perfect for daily/prolonged use. Appearance-wise, pakkawood has a natural wood-like look and a natural glossy finish once it’s ground and polished during the production process. There’s no need for a spray-on product to keep it shiny and the finish is scratch-resistant. Moreover, it comes in various striking colors and patterns that vary depending on the particular composition of the veneer layers. It’s mostly made to look like natural wood but it can be dyed to mimic a wide range of common hardwood types including oak, walnut, zebrawood, chestnut, and more.

Other Recommended Wood Species

1. Oak

Pros

- It’s affordable and readily and abundantly available

- It’s strong and stable enough to withstand prolonged use

- It’s warp resistant and can survive high heat levels

- Provides a more firm grip overall

- Visually appealing and easy to carve and inscribe

Cons

- Raw oak has tannins that can cause rusting easily

- Oak tends to be fairly brittle

Why we choose it

Oak is a type of hardwood and it’s a very popular choice for knife handles and other specialty items due to its great physical properties and the fact that it’s readily and abundantly available. It has fine grain, and it’s so strong and stable that it can withstand prolonged use and even survive high heat levels. Its toughness and durability makes it suitable for knives that see a lot of use. The other advantage of oak wood is that it’s able to retain its shape. It doesn’t warp or decay over time, so it’s really long-lasting compared to other types. Beyond the strength and durability, oak wood handles tend to provide users with a more firm grip overall. Moreover, glue easily adheres to it which makes fixing the knife’s tang in place effortless.

This wood is also visually appealing which gives the knife a beautiful aesthetic look. It mostly comes in lighter color shades, ranging from light beige to golden brown depending on the species of the Oak tree (over 60 species are available). Due to its light coloring and grainy appearance, this wood can easily be dyed, stained, lacquered, or otherwise tinted when finally sanded to create a distinctive and appealing look. It takes staining very well, so if you want a rich, deep color with a naturally rich hue just like cherry wood, then staining it is the way to go. Oak wood is pretty easy to work with too. It’s tough yet soft enough to carve and inscribe hence knife makers are able to add beautifully crafted artworks to the handle after its finished.

2. Cocobolo

Pros

- Incredibly dense and stable hardwood

- It can handle great abuse for many years

- It’s resistant to rot and insect infestation

- Naturally oily hence not affected by wet conditions

- It gives the user a decent grip and control

- It’s available it various colors that darken with age

Cons

- The oils inside it pose difficulties when gluing

- It can be allergic to some users

- It’s a bit more expensive compared to other types

Why it’s the best

Cocobolo wood comes from Central America and is most often used on handmade custom knife handles, and with good reasons. It’s an incredibly dense, stable, and resinous hardwood that’s also highly resistant to rot and insect infestation or attacks, especially from pests. It’s a wood that can last a long time regardless of how much you use it, making it perfectly ideal for your everyday kitchen knife as well as hunting knife. This wood also does give users a good grip and control while slicing through ingredients for cooking. It’s equally a naturally oily wood, meaning it’s very stable and resistant to the effects of wet and dry conditions. The high oil content inside it also has the effect of really killing off various pathogens that do end up on the surface hence helping keep the handle sanitary.

Cocobolo is highly prized too for its range of colors which is why it’s widely used for handmade custom knife handles. It has a rich, striking pattern of color that ranges from brown, orange, red, tan, and yellow, interspersed with streaks of purple or black. The colors darken after a year or two, sometimes to almost completely black. Despite its beauty, those natural oils often pose difficulties when gluing, plus if the surface isn’t properly sealed before finishing, the oil then can cause the color to bleed onto the surrounding surface. Cocobolo wood can equally be allergenic. It can cause eye, skin, or respiratory irritation, and even nausea.

3. Maple Burl

Pros

- Commonly used to make kitchen knife handles

- It’s durable thanks to its density

- Easy to use and offers a comfortable grip

- Features a naturally beautiful pattern

- Can be dyed in various colors to enhance aesthetic appeal

Cons

- Must be stabilized to prevent it from cracking

Why it’s the best

Maple burl is commonly used in making knife handles. It comes from the big leaf maple tree. The wood is mainly obtained from an outer growth known as burl on the tree and it’s preferred as a knife handle due its great density and durability. It also gives the handle a comfortable grip and it’s easy to use. Despite its strength though, maple burl wood has to be stabilized with resins so as to prevent it from cracking from regular use. In terms of appearance, most types of maple trees tend to be sensitive to weather but the grain pattern of maple burl is naturally beautiful hence it can add aesthetic appeal to any knife. The burl wood can as well easily be dyed in various colors, appealing to some chefs.

4. Cherry

Pros

- Fairly hard and stable for moderate use

- Resistant to both insect and fungal attacks

- Quite easy to work with and offers a firm grip

- Rich reddish-brown color makes the handle look elegant

- Color darkens with age, making the handle more beautiful

Cons

- It can give a blotchy finish when stained

- May not last as long as most hardwoods

Why it’s the best

Cherry is also a preferred wood for making knife handles, especially for those who want a more rustic or classic feel without sacrificing aesthetics. It’s fairly hard and stable hence moderately durable depending on whether you have the heartwood or sapwood. It’s resistant to both insect and fungal attacks, meaning it has the capacity to last for long and as such, suitable for moderate use. Cherry is equally a wood that’s quite easy to work with and has fine grain that offers a lovely texture which gives the handles a firm grip. It doesn’t cause much hand strain in contrast with other materials.

The fine grain and the lovely texture also make cherry wood look elegant. Its color transforms from beautifully pale when young to a rich reddish-brown when it ages. It gives the handle a polished, elegant look. The red-brown color darkens with age, making the handle look even more beautiful and classic.

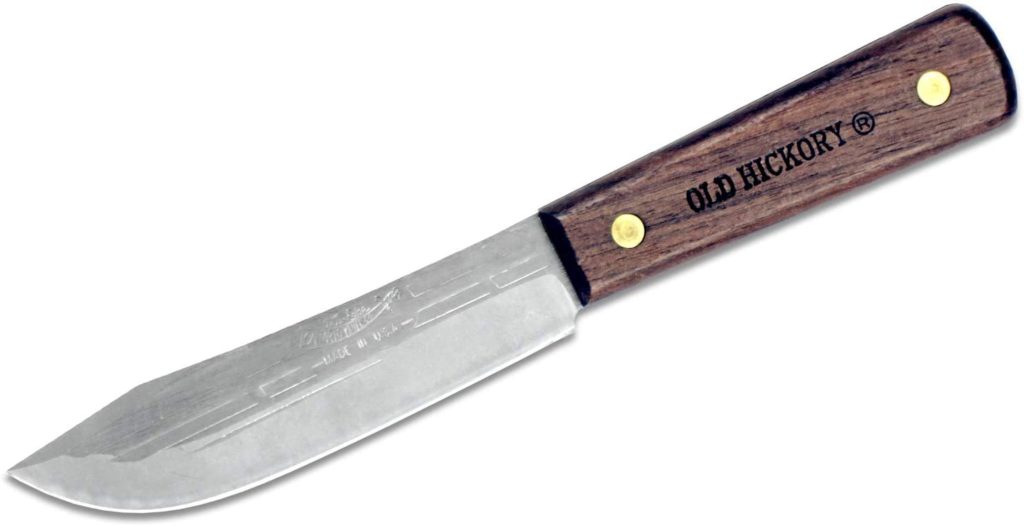

5. Hickory

Pros

- Good hardwood for knife handles

- It’s strong, flexible, and shock resistant

- Relatively durable and resistant to damage

- Can carve into any shape for a comfortable, firm grip

- Provides solid grip even in wet environments

- Beautiful color and pattern that makes it look attractive

- Takes glues, stains, and paint finishes pretty well

Cons

- It tends to warp over time

- It’s prone to decay and insect attacks

- Can be difficult to work with if your tools don’t have sharp edges

Why it’s the best

Hickory wood has been used to make handles of all varieties, including knives for years. It’s a classic and attractive choice due to its strength, flexibility, toughness, and shock resistance. Its density makes it stable, and relatively durable, and resistant to damage hence ideal for knife handles. The hickory wood texture is medium, featuring large open pores. It can be carved easily into almost any ergonomic shape for a comfortable, firm grip that doesn’t strain the hands. Hickory handles also offer excellent grip even in wet conditions making them suitable for use in the kitchen. The wood has a light creamy color and brown streaks run throughout the entire length which gives it a quite handsome look, especially when attached to a steel blade. Hickory also does take glues, stains, and paint finishes well.

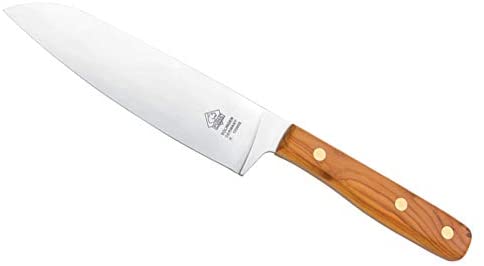

5. Olive

Pros

- It’s very dense and offers great resistant to abrasion

- It can last for many years with proper care and maintenance

- Easy to carve into an ergonomic shape for a firm grip

- An attractive color that makes the handle look beautiful

- Affordable and doesn’t need stabilization once dry

Cons

- It’s susceptible to insect infestation

- It’s a bit difficult to dry

- Not really suitable for use in wet conditions

Why it’s the best

Olive is one of the most popular trees because of its biblical and historical roots. It originates in Europe (Russia), Eastern Africa (Kenya, Tanzania, and Uganda), and the Mediterranean as a whole. The Middle East and parts of North Africa are also sources of good olive wood. This hardwood has a fine and even texture, and it’s a suitable choice for knife handle manufacturing as it’s very dense which makes it resistant to abrasion. However, it’s moderately durable and known to be susceptible to insect infection, but with proper care and maintenance, it can last for many years.

Occasional or regular application of oil on the wood surface can as well help it withstand probable damages from the knife’s heavy and prolonged use. Olive wood can also be carved easily into an ergonomic shape to provide a solid grip. It’s a very attractive wood too, featuring a light yellow to brown heartwood color with black or dark brown streaks running through the length. It has a really appealing look and the color darkens as the wood ages, giving it an even richer appearance and a lot of character. Olive wood is equally not very expensive and although it’s difficult to dry, once dry it doesn’t need stabilization.

6. Birch

Pros

- It’s readily available everywhere across the world

- It’s dense, strong, durable, and highly resistant to damage

- It’s water resistant and it doesn’t decay very fast

- You don’t have to use glue to fix the handle in place

- Easy on the hands and offers a comfortable, solid grip

- Comes in beautiful colors and its polished brightly

- Easy to maintain and can be restore when its discolored

Cons

- It tends to warp over time

- Can break easily if warped which could be hazardous

Why it’s the best

Birch is certainly one of the most common species of wood used to make knife handles and this is mainly because of the availability of the birch trees which are located everywhere across the globe. The trees also grow very quickly and need very little processing before they are ready for the market, cutting down the production cost for manufacturers. The wood is usually stabilized to form birch laminate which is a super dense and much stronger wood than the normal birch. It’s very durable and highly resistant to damage as a result of the lamination process. It’s amongst the best woods for making knife handles. It’s water resistant and it doesn’t decay very fast. It can hold up to frequent use even with a lot of contact with water.

Birch wood is equally easy on the hands. It offers a comfortable grip and can be carved into various shapes to improve its grip. It makes the perfect handle for those that do a lot of slicing. Moreover, it doesn’t need glue, which makes it even more convenient for a knife handle. The colors are often bright and showy, providing an exquisite appearance. They can even look a little unnatural in certain patterns. Besides that, birch laminate handles are the easiest to maintain, plus when they become discolored, it’s possible to restore them.

7. Eucalyptus

Pros

- Easy to find and relatively self-sustaining

- Grow easily and quickly, and are not endangered

- Gets quite hard and strong as they dry, hence very durable

- Highly resistant to water and rot, ideal for use in wet conditions

Cons

- Takes pretty long (at least 2 or 3 years) to really dry

- Has to be properly seasoned to be used as knife handle

Why it’s the best

Eucalyptus is a hardwood and there are about 350 to 500 species, each having its own properties. However, they all grow fast and straight, and get harder as they dry which makes the wood strong and highly durable, ideal for knife handles. This wood is also highly resistant to water and rot hence suitable for frequent use in wet conditions. However, it has to be really dry (at least 2 or 3 years) for it to reach its full potential. It as well has to be properly seasoned, plus any surface that needs to be glued has to be wiped down with white spirit in order to remove the oil. In terms of looks, eucalyptus isn’t the most attractive wood but it has a decent nice color that can work for a knife handle.

8. Pine

Pros

- It’s easy to find, cheap and fairly self-sustaining

- It grows easily and relatively quick

- Good for knives that see only occasional use

- Can be stabilized to harden it and extend its lifespan

- Easy to carve to a shape that offers a comfortable grip

Cons

- It can’t last long and hold up to abuse like hardwood

- Absorbs water more readily and it’s less resistant to rot

- Not quite attractive and doesn’t finish well

Why it’s the best

Pine is softwood, even its burl. It’s easy to find like many other softwoods such as spruce and fir and it’s relatively self-sustaining. It grows easily and quickly, plus it’s not endangered like a good number of hardwoods. However, it encompasses many different species and the growing conditions of one species can have a major effect on the wood/timber of a particular tree. Even though it is softwood, pine can still make an “OK” knife handle, especially if the particular species features harder wood or it is old growth with lots of tightly packed growth rings. Pine is also easy to carve hence can give you an ergonomic handle shape that’s comfortable to hold.

Unfortunately, being softwood, it can’t really make a good and durable handle because it’s less dimensionally stable, less strong, and does dent more easily. It can be more useful if hardened through stabilization but the process will take a bit more effort. Moreover, the wood will still wear and “ding” quicker than hardwood, even if stabilized. Pine is a little boring too with regards to looks. It’s very porous and doesn’t finish well.

9. Mulberry

Pros

- Decent hardwood that’s durable enough for a knife handle

- Good weathering properties and resistance to insect attacks

- Can be curved to provide a comfortable, solid grip

- Has an attractive color and good natural luster

- Turns, glues, and finishes well

Cons

- Not abundantly available compared to other types

- Comes at a slightly higher price

Why it’s the best

Mulberry is a decent enough hardwood for a knife handle. It’s nothing superb, but will definitely work. It’s pretty durable, with good resistance to insect attacks and weathering. It can also be curved to offer a comfortable, solid grip. As for the appearance, the heartwood is a golden brown color that darkens to medium/reddish brown over time. The sapwood is a pale yellow-white color. Generally, the overall appearance is similar to Osage Orange wood. It’s attractive and the grain of the wood is straight, featuring a uniform medium texture. It has good natural luster and turns, glues, and finishes well.

How to make a wood knife handle?

Making wood knife handles isn’t really a daunting task. Here are some simple steps you can follow to create a beautiful handle:

- Collect all the necessary materials you’ll need to make the knife, which include power tools, wood, and glue.

- With everything set, mark out the blade’s shape on the steel piece and begin cutting it exactly along the marked line using a hacksaw.

- Take you knife-shaped, shiny metal and give it an edge

- Brush over the edges lightly until they attain the right angle

- After brushing that, then temper the metal

- From there, weld the hilt in place as the handle is still bare metal and clamp it and start the polishing, sanding, and filing process. You can skip the above steps if you have a ready-made blade with the bare metal handle/tang.

- Drill five holes into the wood chunks and knock through to create a slit

- When you’re done, slit each layer of the chunks onto the handle and then put some glue. Repeat the process again.

- To form the handle, start by cutting vertically down the hardwood piece to create the shape of a knife handle.

- Once you’re satisfied with the shape, you can start sanding and then nicely polish it with some wax to give it a good luster

You can basically follow these simple steps to create a custom-made handle of your choice. However, you’ll need to use suitable abrasives when it actually comes to shaping and finishing the knife scales – choosing the correct abrasive will certainly give you better results.

Aluminum oxide abrasives are the most common option for woodworking and are usually used for shaping knife scales too. However, if you are sanding hardwoods, then it will be safe to use a zirconia or ceramic abrasive for longevity. You’ll need to watch your speed so as to avoid scorching.

Many knife makers prefer using sanding belts for shaping scales since they are great at getting into tight spaces and also conforming to curves. It would be good though to consult an abrasive specialist should you need help deciding which abrasive would best suit your application.

Once you make your wooden knife handle, it will need proper care to ensure its longevity. Since the wood often dries out, applying some few drops of oil on its surface and then allowing it to soak will help prevent it from cracking and also keep it strong. However, if you use stabilized wood for the handle, then you wouldn’t have to do so because it has already absorbed resin during the stabilization process which would sustain it for long.

FAQ

Aren't the darker woods harder than lighter colored woods?

Wood basically comes in various colors and strengths based on the type of tree it came from. However, they can be put in two main categories when it comes to color, that is, darker and lighter colored woods. Dark woods such as ebony, mahogany, cherry, desert ironwood, rose wood, and others are usually harder than lighter colored woods because they are typically hardwoods taken from harder trees.

These trees take longer to grow (up to 100 years) to maturity hence will often become much denser, stronger, and darker. The high density of their wood is what causes the dark color and it’s also what makes them much stronger.

Light-colored woods are almost always softwoods hence are usually softer compared to their dark-colored peers. These woods come from softer trees that grow faster hence are less dense and not hard or dark. They typically have a distinctively light grain.

Of course, this isn’t always the case. There are always exceptions to the rule when it comes to wood species. While it’s true that dark woods far outstrip the strength/hardness of even the toughest light woods, there are some light-colored woods out there that can put weaker dark woods to shame. Some good examples are yellow pine, Douglas fir, and wood from hemlock. These are also light-colored softwoods but they are just as strong as some dark woods.

Matters are confused even more when you consider that although hardwoods are typically darker in color, there are some varieties like oak, maple, ash, beech, and poplar that are naturally light-colored. Generally speaking though, dark woods are usually stronger than light-colored woods.

Are there unique hardwoods just for knife handles?

Yes. There are many different unique and exotic hardwoods used to make knife handles. Most of these hardwoods are rare to find which makes their prices to be very high. The more rare the tree, the more expensive it will be. Some of these unique and exotic hardwoods include:

Pink Ivory – also called Red Ivory, this is an African wood that only grows in Mozambique, Zimbabwe, and some parts of South Africa. It has an incredibly high wood density which makes it super hard, very durable, and also highly resistant to decay. Its color ranges from pale orange to bubblegum/neon pink, plus it can even come curly. Color does fade down to almost medium orange gold, but still the bubblegum pink hides just below the surface. The wood is super expensive due to its uniqueness and the fact that it’s hard to find.

Wood from Peach Trees – not to be confused with “peachwood,” wood from peach trees is very limited mainly because there’s hardly much wood on peach trees, plus they usually crack or splinter easily. However, the wood is fine and it’s coveted by knife makers. It’s pretty rare and unique but great for knife handles because it’s dense, hard, durable, and attractive.

Koa Wood – Koa only grows in Hawaii. It’s a much sought after wood and very expensive due to its physical properties and beautiful appearance. Color ranges from a brighter yellow to gold to red to pink or brown hue. Very few woods possess such a range of colors. It often has a curly figure and fine texture, and takes a high lustrous finish. It’s almost a metallic-like curly wood. It’s fairly easy to work with and it’s very strong and durable which makes it suitable for knife handles. It’s the most sought after curly wood and can reach seemingly absurd prices.

Desert Ironwood – this is a classically beautiful wood, native to Southern Arizona and Mexican Sonora desert. It’s incredibly hard, almost impossible to scratch, extremely dimensionally stable, and has a beautiful figure. It’s high hardness and very fine grain makes for rigid knife handles. Being very heavy too, it’s often used to counterbalance longer blades. It features a beautiful color and pattern. Color can range from light to golden brown to dark brown, which becomes darker (nearly blackish) with age. Desert ironwood is extremely expensive due to its unavailability but it’s held in high esteem by many custom knife collectors.

Bloodwood Satin – also called Cardinal wood, this is a rare and exotic wood that originates from Central America (mostly in Brazil) and the Caribbean. Knife handles made of this wood are very comfortable and beautiful. Its color is an intense deep crimson red. The hue darkens with age, further bringing out its natural beauty. The wood also takes a high lustrous finish. It’s dense and hard with linear fine grains. It’s resistant to warping and shrinkage hence very stable and durable when used to make a knife handle.

African Blackwood – considered the original ebony, this is one of the hardest, densest, and most expensive woods in the world. It’s challenging to work on either with hand or machine tools and its trees are already almost threatened which is why it’s very expensive and hard to find. Nonetheless, it’s a highly prized wood for knife handles because it’s harder and more stable than its peers like ebony. It’s also far more resistant to crack, decay, and warping hence very durable, although not quite resistant to insect attacks. The grain is incredibly fine and straight. They are more pronounced and have a good texture. The wood allows intricate carving hence can take incredible detail. It can also be carved into fine shapes and equally hold crisp detail. It’s often completely black with silver gray grain lines running through it. However, the color can as well lighten to a dark brown or purplish hue giving the handle a nice subtle beauty.

Ebony – found in Africa and East Indies, ebony is a luxurious wood that has a rich darkness that’s extremely elegant. While it’s almost blackish, it does contain some degree of color depending on the type. Black ebony is generally jet black but sometimes has lighter streaks while the Macassar ebony is black but with blonde or gray tan, or reddish-brown streaks. Both are fine textured with metallic luster and finish smoothly. They have a high glossy look when polished which gives their dark complexion an unquestionably elegant appearance. The wood is highly robust, strong, and offers natural resistance to splintering, insect infestation, and other types of damage hence it’s extremely durable and perfect for making ornamental and custom knife handles. It also provides a firm grip while holding it. Owing to its eye-catching appearance and resilient performance, ebony is very expensive and highly sought after. Ebony trees are also scarce and slow-growing which makes them unique and endangered.

Bocote – this is an exotic wood that makes beautiful, unique knife handles. It’s found mainly in Mexico and Central America. It’s quite dense (almost similar to some rosewood), hard, and durable. It’s also wear-resistant; although it’s susceptible to insect attack hence requires good care. It has a light honey yellow color with bold, dark stripes/streaks running through it, creating a very striking pattern. It’s often highly figured with eyes and has fine texture with oily appearance and gorgeous luster, so it makes a stunning knife handle and polishes well. Like ebony, bocote is a rare but highly sought after wood hence it comes with a hefty price. Generally, it’s hard to find home knives with handles made of bocote. It’s mostly ideal for handles of custom and ornamental knives.

Amboyna Burl – amboyna is considered a classic wood for knife handles, often used on show knives and other high end user blades. It’s relatively rare but highly sought after, so like the rest, it falls under the most expensive woods category. Despite that, it’s certainly worth the money considering its beauty and functionality. The wood is dense and hard. It resists oxidation hence its very stable and strong enough for use on everyday kitchen knives. The only limiting factor is the hefty price which makes it more appropriate for artisan knives that get little wear. It has beautiful coloration with a denser burly pattern with swirls and eyes. It comes in various colors including deep vivid red, yellow, golden brown, and orange with snow-white sapwood. It takes an amazing finish.

Importance of Availability and Sustainability of the Wood Specie for the Wood Knife Handles

Availability and sustainability are core topics today when it comes to wood and other natural resources. The key factors that really come into play with regards to sustainability of the wood used to make knife handles are how easily the tree species regenerate as well as whether or not they are readily available in the area.

Therefore, a good rule of thumb, especially when looking for the ideal wood for knife handles is finding out what’s the most sustainable wood species available in the area and whether or not it’s eco-friendly to use.

Some of the more beautiful and exotic hardwoods such as ebony, desert ironwood, and bloodwood satin (Brazilian mahogany) are incredibly rare and endangered, plus grow very slowly (can take up to 100 years just to mature). They may seem like the perfect wood for custom and ornamental knife handles, but it’s best to avoid them.

There are many hardwoods, though, which are not really endangered and are relatively inexpensive like some of the exotic woods. Some good examples are maple and birch which are easy to find and fairly cheap than the less eco-friendly, albeit beautiful options.

Birch trees, for instance, are one of the most common hardwoods around the world and are very environmentally friendly. They also grow rather quickly and require very little processing and maintenance. Rosewood is another good option when looking for hardwood for making knife handles as it’s quite abundant all over the world.

Most of the softwoods like pine, fir, and spruce are equally easy to find and cheap. They are relatively self-sustaining and grow easily and quickly. They are not endangered and although they take a little more effort to stabilize them, they can make durable and beautiful handles. They can be a good environmentally-friendly alternative to most of the rare and more expensive hardwoods.

In general, when looking for the best wood for making handles for your knives, it’s important that you consider and search for wood species that are sustainable, available, and ecologically sound to use, especially if you are an environmentally conscious knife maker.